The Voortman V807: Advantages of Robotic Coping

If you own a fabrication shop, you know how important it is to have reliable and efficient equipment that can produce a wide variety of shapes and sizes. That’s why we recommend investing in the Voortman V807 robotic profile processor, which is capable of processing nearly any kind of structural steel shape that needs to be produced. Let’s take a look at some of the benefits this machine offers.

The Voortman V807 robotic profile processor is capable of processing nearly any kind of shape that needs to be produced. Rat holes, seismic structural design connections (like slotted web and “dog bone” cuts), copes at the start or end of a product, block outs, holes in every size and shape, weld preparations and marking on all 4 sides are just some examples of possible cuts the V807’s robot can process thermally.

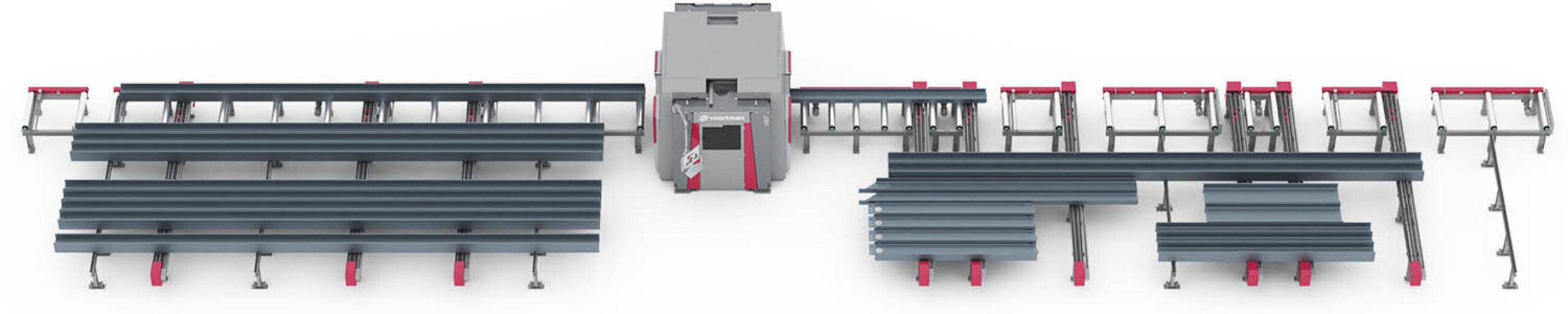

The Voortman V807 robotic thermal cutting machine as all other machines is delivered with the VACAM Operating Software this means all machines speak the same “language”. This makes the V807 incredibly versatile and can be part of a complete new layout including roller conveyors and cross-transports connected to other Voortman processing machines, or as a stand-alone processing center.

We’ll work with you to come up with a solution for any situation you face – including implementation into an existing production line, or outside loading and roller conveyors. The roller-feed measuring system is completely integrated in the machine housing and offers complete freedom for planning and expansion in your workshop. You can start with a small layout and easily extend the machine with more automated logistics or add complementary machines at a later time as your business grows. Voortman makes machines that can grow with your company seamlessly when extra capacity is needed without increasing labor costs.

After installing a machine or production line, Voortman installs a net of safety measures. These safety measures comprise of light curtains, emergency cords and emergency stop buttons. Voortman has made it one of its priorities to deliver a safe production line, yet not hold up production if the operator needs to enter the safe zone. This is accomplished by using gated light curtains allowing loading and unloading while the machines continue processing, and by delivering remote controls with a kill switch that operators can use when carrying out tasks inside the safety zone.

We often get asked if there is one ideal application solution capable of addressing all processing needs. The most versatile application process in most cases is robotic coping with a V807. Find out more today. Contact us today at info@jpsint.com